Raw materials such as copper, cobalt, and rare earth metals are scarce on land. Deep-sea mining companies, therefore, want to dig for them on the seabed.

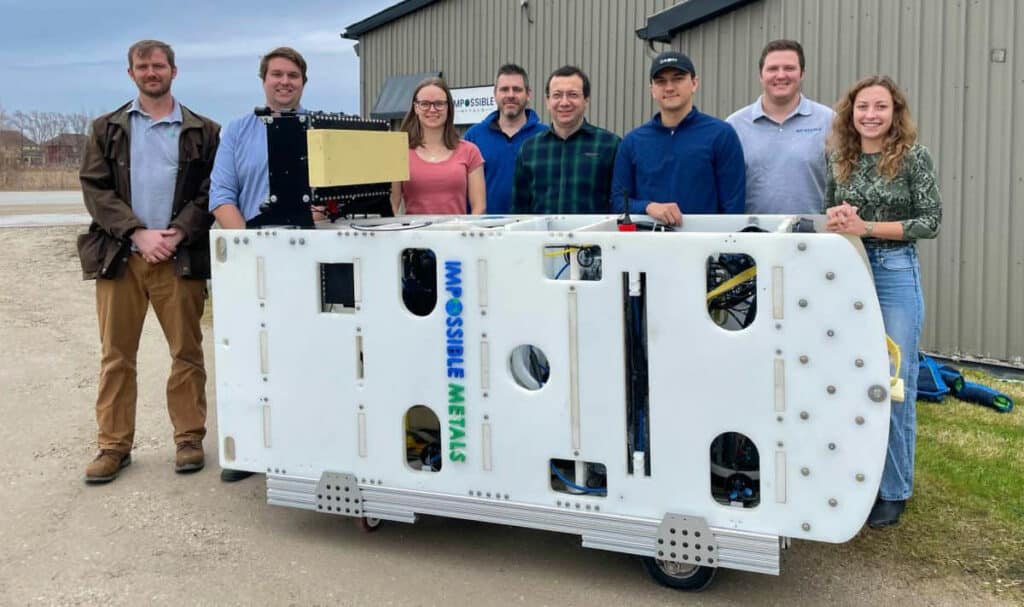

One of them is the Canadian company Impossible Metals. The company announced that its first proof of concept, an autonomous underwater robot called ‘Eureka 1’, has successfully completed its first trial of selectively harvesting rocks in an underwater environment.

This approach for the collection of polymetallic nodules, rich in critical battery metals, requires three key enabling technologies to be invented by Impossible Metals: a buoyancy engine, a fast underwater robotic arm, and an AI-driven computer vision system to find nodules and marine life on them.

Polymetallic nodules, also called manganese nodules – with a size ranging from that of a potato to a head of lettuce – lie on the seabed sediment, often partly or completely buried. They consist mostly of iron and manganese but also contain valuable metals such as cobalt, copper, nickel, or titanium and, to a very small extent, rare earth metals, platinum metals, or tungsten.

These raw materials are important for the electronics industry, among other things, which is why the possibility of mining these and other raw materials from the seabed has long been considered. However, deep-sea mining is controversial because it affects the seabed ecosystem over a long period of time. That’s not the case with Eureka 1, according to Impossible Metals.

“This shallow water milestone demonstrates the progression of our principles of avoiding serious harm to the seabed by replacing dredging technology with an alternative that prevents biodiversity loss and large sediment plumes,” said Oliver Gunasekara, CEO & Co-Founder.

Eureka 1 is designed to collect manganese nodules at depths below 5 km (3.1 miles), deploying from a ship at the surface and sinking until it’s right above the seabed. The AUV robotics fleet will be developed using “pick and place” manipulator technology to harvest nodules individually, minimizing disturbance of the sediment and seafloor ecosystems. Image sensing technology will identify megafauna present on the nodules and will leave those nodules untouched, allowing for the preservation of nodule-dependent fauna.

“The success of this first proof of concept is a major milestone for the company toward demonstrating the technical feasibility of using an autonomous, AI-driven system to hover above the seabed and selectively harvest nodules,” said Jason Gillham, CTO and Co-Founder.

Impossible Metals plans to have its robots developed and ready for large-scale deployment by 2026. That will not only be a huge step forward for sustainable critical metals but will also change the economics of critical rare metal resources – positively impacting global supply chains. This is also a big step toward a green economy by finding better ways to mine essential minerals. It will be important because the demand for these metals will keep going up for the next few decades.